LEADERSHIP

Since its founding in 1956, Tong Cheng Iron Works Co., Ltd. has been producing SWAN-branded air compressors for over five decades. With ample manufacturing experience and technical competence, the company has built integrated production in-house, able to handle parts casting, design and development through to molding.

INTEGRITY

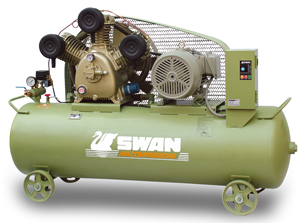

With a work force of 750 worldwide, Tong Cheng has established three production bases in Taiwan, China, Thailand, two processing and assembling plants in Vietnam and Indonesia, six fully-owned subsidiaries and 70 distributors in over 50 nations, ensuring close ties with global customers and efficient production. It has also supplied OEM air compressors for train braking system on the French TGV. With TUV ISO9001 and CE-certified, swan air compressor supplies mainly oil-less, rotary screw, industrial piston, water cooled, silent air compressors in tandem with air dryers and filtration equipment. Tong Cheng also accepts custom orders for air compressors and screw compressors for transportation, medical, pharmaceutical, electronics, textile, laboratories, food and beverage, water treatment facilities, chemicals, refineries, industrial gases, power generation and general manufacturing operations.

EXCELLENCE

Swan air compressors are designed for long lasting industrial use. Energy saving, low noise, high reliability, long service life, low maintenance cost are all the special features of swan air compressors. Among different type air compressors, the screw type TS series ensure the large displacement and minimal power consumption; the oil-less type SD series provide much cleaner compressed air; the piston oil-lubricated N type features a built-in lubricating system to bear continuous heavy duty loading, suitable for round-the-clock operations.

Besides applying rigorous quality control and testing standards, Tong Cheng insists on 100% inspection in the final quality-control stage, aiming for zero-defects and maximum effectiveness for end-users.