Win Ho Technology Industrial Co., Ltd. is a quality manufacturer that specializes in high-speed precision lathes and inverter transmission lathes, and the products are backed up by efficient customer service.

The company’s inverter transmission lathes feature seamless speed change, able to cut 8mm~200mm into workpieces at 1,000 rpm. Spindle speed is controlled by a rotary switch.

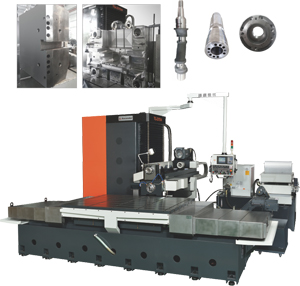

With FAG or SKF precision bearings installed on spindle, the high-speed precision lathes with a machining length of over 4,300mm have a one-piece base providing high rigidity and low vibration. Gears are specifically built in the headstock box, ensuring seamless speed shifts when the machines are engaged in heavy-duty cutting. The lathes have a universal gearbox for both imperial and metric threading, eliminating the need to change the gears when threading different pitches. A conversion table is attached for additional convenience.

In recent years Win Ho has developed bigger lathes with a maximum workpiece swing of 830mm and a length topping 4,300mm. Spindle bore measuring 120mm across enables the lathes to work on large-diameter workpieces. With bearings on the bottom, tailstock can be moved easily, and their thermally-treated Meehanite bed casting features high hardness, wear-resistance, and a long lifespan.

Win Ho has three major management concepts: Innovation--continually upgrading its facilities and developing new technologies to meet market need; Determination--always striving to produce the best quality of lathes for all its customers; and Application--fabricating the right machines to the right job.

Win Ho’s business is booming. It shipped over 1,200 machines in 2012, driving sales for the year up 25% to NT$365 million (US$12.5 million at NT$29: US$1). To cope with the flood of orders, the company is constructing a new production site in the second phase of the Taichung City Precision Machinery Innovation Park in central Taiwan.